Dried noodle production line

Category:

E-mail :

- Product Description

- Product Parameters

- Related Videos

- FAQ

-

The optical,mechanical and electrical integrated low-temperature suspended dried stick noodle production line designed and manufactured by the company, has the characteristics of advanced drying process, unique and novel structure, stable and reliable running, high yield of finished products, high degree of automation,convenient operation and low operating cost, and is ideal equipment for large modern dried stick noodle production enterprises. The drying room mainly adopts low-temperature low-speed drying process, unique steel wire rope transmission device is

used,lifting hook is fixed on the steel wire rope, and noodles are smooth in operation and do not have oil stains. The heat supplying system can use steam, air energy or hot water as heat sources. For pipe arrangement, double-circuit heat supply mode is adopted, temperature balance at two ends of the drying room can be realized, and the moisture removal amount is conveniently and rapidly adjusted and controlled. The produced fine dried noodles have uniform, consistent color and chewy, tasty and pure after being cooked, Different types of high and middle-grade fine dried noodles can be produced. The low-temperature suspended dried stick noodle production line can work in any external environment and is the most ideal complete equipment for producing fine dried noodles at home and abroad at present.Product Parameters

Model No. Production Capacity

(kg/8 hours/shift)

Size of FactortyLength"Width"Height)

Can double the width of a single layer layout

Installed Capacity(kw) Workers(without

packing process)

GMS-350 3000 60x8x3.5x two-story 40 4 GMS-450 5000 65x10x3.5x two-story 70 4 GMS-550 7500 72x12x3.5x two-story 80 6 GMS-650 9000 78x13x3.5x two-story 95 6 GMS-800 11000 84x16x4.0x two-story 105 6 GMS-1000 15000 90x18x3.5x two-story 120 7 GMS-1200 18000 90x22x4.0x two-story 130 7 Low-temperature Suspended Type Dried Stick Noodle Production Process

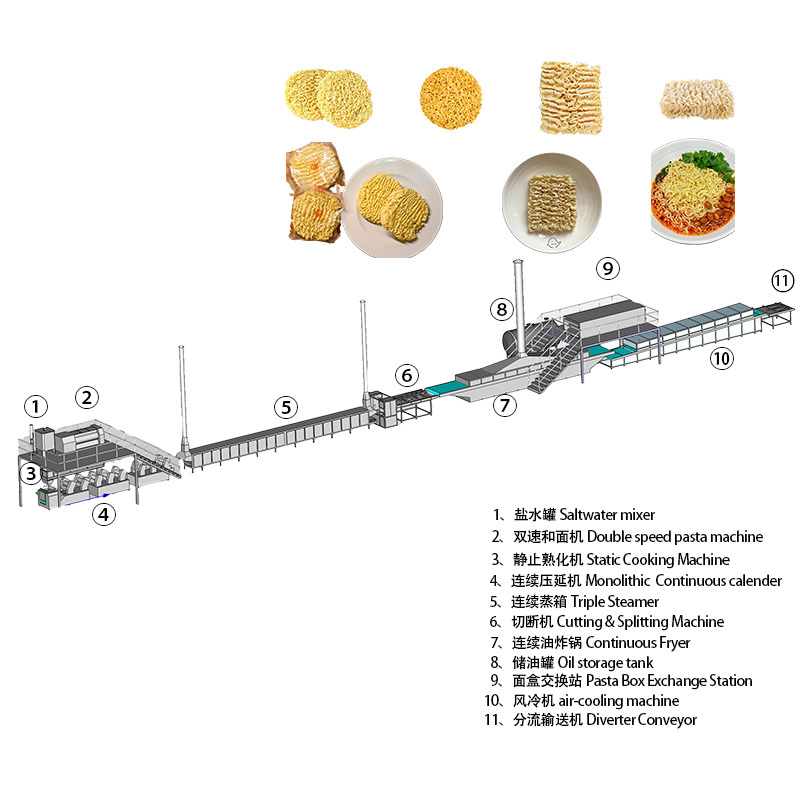

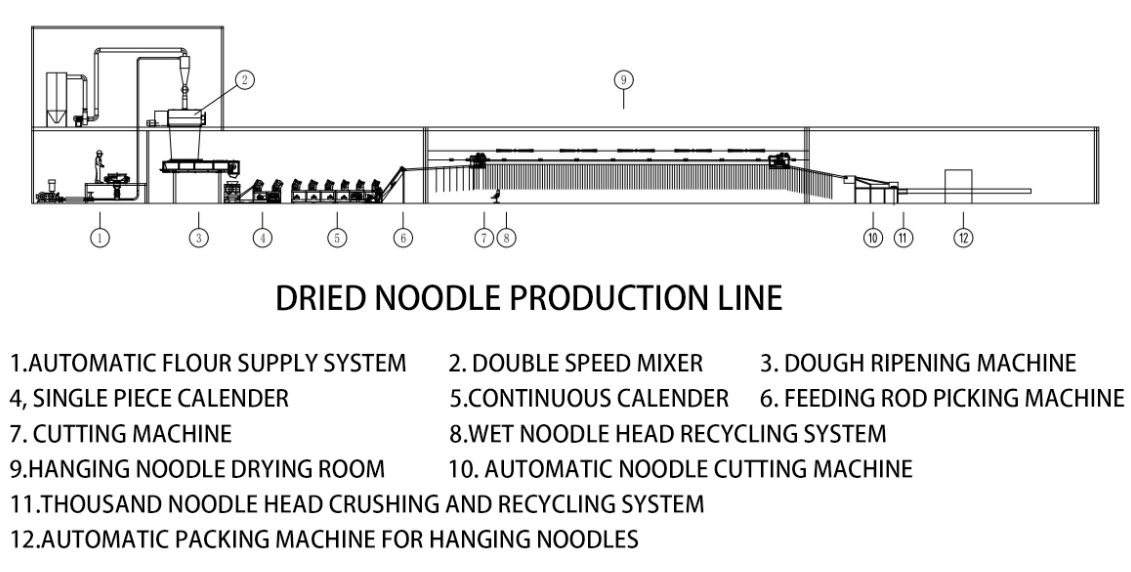

Automatic Raw Material Supply - Mixing & Measurement Of Salt And Water- Double-Shaft Double-Speed Dough Making (Continuous Dough Kneading)- Dough Ripening-Monolithic Rolling-Dough Sheet Aging-Continuous Rolling- Picking Out Noodles With Sticks-Automatic Elevating -Shearing-Low-Temperature Suspended Low-Speed Drying-Automatically Removing Off Shelves-Cutting-Packaging-Warehousing

IntegratedTranslation Dried Stick Noodle Production Line

Automatic Raw Material Supply - Mixing &Measurement Of Salt And Water - Double-shaft Double-Speed Dough Making (Continuous Dough Kneading)-Dough Ripening-Monolithic Rolling-Dough Sheet Aging-Continuous Rolling-Picking Out Noodles With Sticks- Automatic Elevating -Shearing-Translation Type High-Humidity Drying-Automatic Removing Off Shelves-Cutting-Packaging-Warehousing

Equipment Configuration Sheet

1

Powder supply system

1.Roots fan

2, vibrating screen

3, positive pressure off the wind device

4. Sacron stainless steel

5. Disloader pneumatic

6. Dust collector bag type (including fan)

7. Wind network pipeline

2

Saline mixer

Barrel form: round or four corners.

Including: mixer, mixing bucket, infusion tube, infusion pump.

Materials: agitator, mixing drum, infusion tube, pipe fittings, valve is made of SUS304L stainless steel;

The infusion pump is made of acid-resistant plastic material.

Use and characteristics: fuse the materials such as easy to fuse with water and water mixing, supply the metering device, to realize automatic control, automatic water intake, automatic switching, and reduce manual intervention.

3

Measurement of supply

installation

Material: metering tank, infusion tubes and valves are made of stainless steel SUS304.

Use and characteristics: the brine mixer stirred liquid, quantitative supply and surface pot and surface, accurate measurement, achieve quantitative automatic water, stable no residue, can be adjusted according to different surface water.

4

Double speed and noodle machine

Including: 1 hopper, automatically open the door for feeding.

Material: face box, shaft, blade and lower hopper are SUS304 material. Ordinary steel or cast iron: transmission parts, chassis, cylinder. Nylon: Locate the set

Use and characteristics: made of the skin of good tensile resistance, not easy to break, good transparency, chewy texture. This machine uses the elliptical biaxial mixing blade, and the surface is more uniform, the effect is more ideal. The reducer belt drive not only ensures the transmission ratio, but also improves the stability of mechanical operation. The box body is separated from the supporting bearing seat of the mixing shaft to prevent material contamination.

5

Static ripening machine

Material: the surface bucket, pot plate is 1.5mm thick, and the crushing shaft is made of SUS304 stainless steel. The frame body is carbon steel. The roller is made of SUS201 stainless steel. The delivery surface belt is a food-grade polyester tape.

Appearance: frosted stainless steel plate and bright light rectangular pipe.

Use and characteristics: the surface conveyor is used to keep the dough transported by the dough machine static and cooked, and to evenly feed the next sheet pressing process.(Frequency conversion and speed regulation) continuous uninterrupted feeding, customized spiral broken feeding surface, semi-closed moisture protection is conducive to the better formation of gluten network.

6

monolithic. Continuous rolling machine

Including: guide per feeding device, surface automatic conveyor belt, roller clearance manual adjustment mechanism. The machine help is for the landing type.

Materials: hopper, feeding rod, bottom plate, head guard plate, machine, frame and transmission parts are made of carbon steel. Scraper: brass material. Press roller: cold hard alloy ordinary casting roll. Delivery strip: a food-grade polyurethane strip. Guard plate: the pressing roller guard plate is nylon.

Application and features: (frequency conversion speed regulation) (photoelectric tracking) automatically calder the good broken surface into a surface belt, extending the surface belt through multiple pressure rollers to the thickness required by the process. Automatic chip, tracking, PLC programming automatic program, the overall design of the unit for a group of integrated, high safety protection level, stable operation.

7

New feeding rod picker

Including: 1 pole bucket, automatically give the pole, upper and lower limit to adjust the noodle uniformity.

Material: storage hopper, cover, SUS304 material. Ordinary steel or cast iron: transmission parts, chassis, machine help.

Use and characteristics: made of noodles, after the rod machine uninterrupted supply, so that the noodles evenly and orderly into the drying room, the equipment built in the upper and lower limit, do not stop to adjust the length of the noodles before and after the inconsistent phenomenon, so that the noodles more neat into the drying room drying, reduce the rejection rate.

8

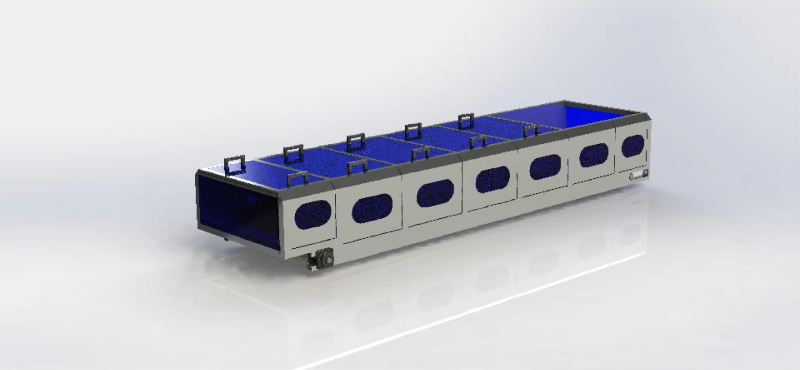

Chain type low temperature

Dryer equipment

Material: hanging noodle hook is high quality steel surface galvanized treatment, main and secondary drive part, fan, fan, respectively for ductile cast iron and high quality carbon steel, the sliding wheel is nylon 66.

Wind circulation system: fan, pressing special air blade, carbon steel special support. Tide discharge and wind repair, etc.

Heating system: the heating medium is steam or hot water (provided by the demander, the demander should connect the heat source to the drying room, the location depends on the process map), the temperature and humidity are controllable and composed of the outer fin pipe.

Uses and characteristics: divided into four temperature zones, cold zone, moisture preservation and drying, and four for cooling. Ensure good noodles taste smooth and elastic, increase cooking resistance and rewater, more market competitiveness.

9

Cut the machine

Including: tool steel blade, lifting wire rod, frame body.

Material: blade is tool steel, wire rod frame is carbon steel surface treatment, cover is 304 stainless steel.

Use and features: cut the end of the noodles with the hanging pole through the cutting machine to make the noodles more neat and beautiful.

10

Hob automatic surface cutter

Cut surface form: hob cut surface

The noodle length is continuously adjustable.

Material: the blade is tool steel; support plate, frame and outer guard are stainless steel; transmission parts are high quality carbon steel, nylon and food grade rubber products.

11

Electrical control system

The main transmission is controlled by frequency frequency control, and consists of four control cabinets:

No.1: control the brine mixing, metering, and dough machine.

No.2: control of ripening, single piece, calendering, rod, drying main drive, shelf.

No.3 + No.4: control cutting, oven, hot fan, damp fan, removal drive, cutting, etc.

Including: programmable controller, frequency converter, shell, contactor, instrument, etc.

The whole line adopts photoelectric sensing tracking, frequency conversion speed regulation, PLC program processing, and added process link programmed system control, which can realize single fine tuning, the whole line linkage, synchronous rise and fall speed.

-

Model No. Production Capacity

(kg/8 hours/shift)

Size of FactortyLength"Width"Height)

Can double the width of a single layer layoutInstalled Capacity(kw) Workers(without

packing process)GMS-350 3000 60x8x3.5x two-story 40 4 GMS-450 5000 65x10x3.5x two-story 70 4 GMS-550 7500 72x12x3.5x two-story 80 6 GMS-650 9000 78x13x3.5x two-story 95 6 GMS-800 11000 84x16x4.0x two-story 105 6 GMS-1000 15000 90x18x3.5x two-story 120 7 GMS-1200 18000 90x22x4.0x two-story 130 7 -

-

Q:How long is your machine guarantee?

A: One year (Calculated from the equipment arrives the customer's side.). We always have new technology support on machine service life period. And welcome to contact us when machine have any problem.

Q: Will you send engineers to install production line in customer plant?

A: Yes, but installation will have extra cost payable by the customer, Or you can get local contractors to do the commissioning and we send one supervising engineer.

Q: Do you supply packing machine?

A: We have long-term cooperation packing machine supplier, we will help tocontact them; Or we share supplier contact information, then customer directly contact supplier.

Q: Will you support each food formula?

A: Yes, we support each product production technology and recipe to customer.

Key words:

Noodle Production Line

Online Messages

Related products

Related news

African mission Come To Our Factory

Mar 12,2024

Wuzhi county business bureau, from Africa project delegation will arrive at our factory at ten o 'clock at noon. First, we will show the finished product to the customer. Secondly, we will play through video to let customers know about all our products, our company is a professional company of noodle machine, and our main products are fried instant noodles production line, non-fried instant noodles production line, frozen fresh noodles production line, stick noodles production line, baby noodles production line and soon. Thirdly, it will give a brief introduction about the production line of fried instant noodles exported to Nigeria. The production line of our company's fried instant noodles is warmly welcomed in central Asia, with high degree of automation and advanced production technology. The instant noodles produced are tasty and crispy.

The New Research And Development Of Noodles Line

Mar 05,2024

According to legend, Quanzhou noodle line has a history of more than 800 years. The authentic noodle line is made by hand. The noodle body is as thin as hair. When cooked, it becomes transparent. Noodles line contains rich and auspicious, long life of a hundred years of good wishes. It is a must to welcome guests and guests, bless congratulations, celebrate holidays and present relatives and friends. In the southern Fujian region, people usually bring thread and egg to celebrate their birthday or other happy events to express their wishes.

Pasta Leaf Production Line: Benefits of Pasta Fermentation

Feb 14,2024

Yeast not only changes the structure of the dough, but also makes them fluffier and tastier, which also greatly increases the nutritional value of buns and bread. Fermented buns and breads are then more nutritious than unfermented foods such as cakes and noodles, because of the yeast used. Eating fermented foods regularly has the following benefits:

Asean food machinery exhibition in Bangkok

Feb 07,2024

The company organized to participate in the Asean Bangkok exhibition this year, the sales manager of our company Mr. Pang leads the team, during the fair, we and the industry technical communication, to understand the different parts of the people's demand for pasta, at the same time, through the exhibition this good platform, here we have seen some cutting-edge products, we also expand the brand influence, reputation, the company's products and services to the nation, to the southeast Asia. At the exhibition, many customers expressed interest in our machinery, sat down to communicate with us, we also exchanged business CARDS, looking forward to future cooperation.