Cooked Fresh Noodle(Oil Noodle、Fried Noodle) Production Line

Category:

E-mail :

- Product Description

- Product Parameters

- Related Videos

- FAQ

-

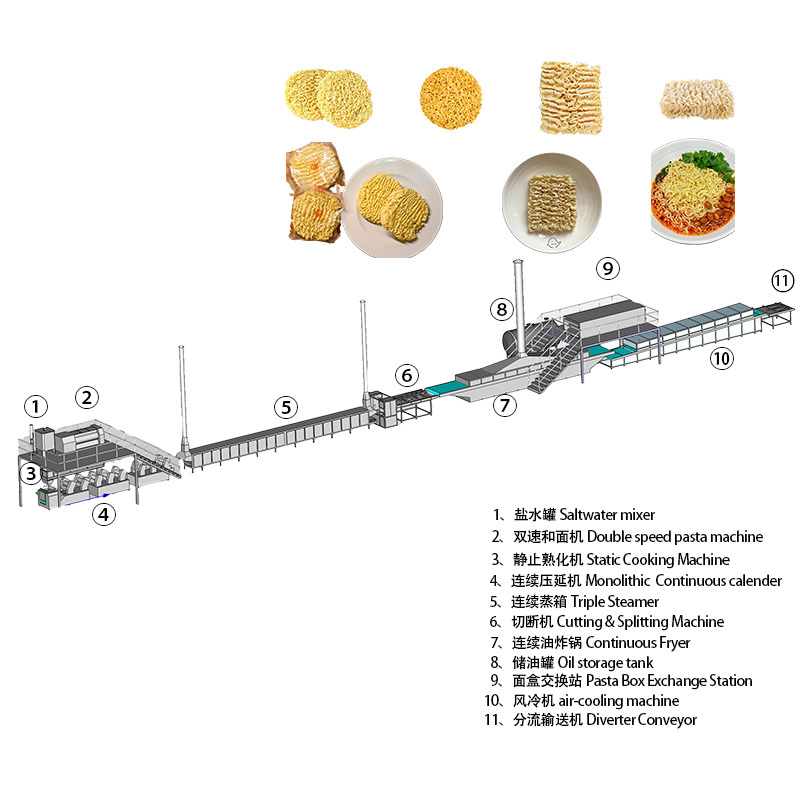

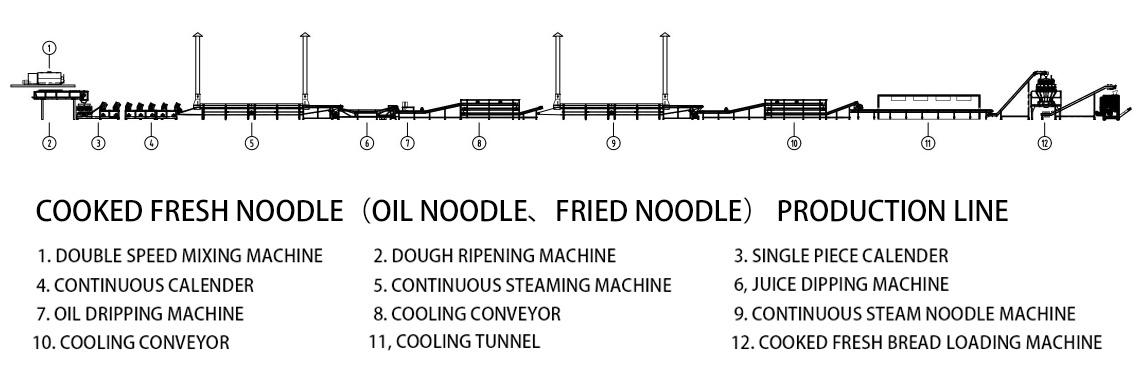

The technical process and equipment for cooked fresh noodles developed by the company and technical colleges, feature strict control on production process links and adopt mechanical and electrical integration mode. Wheat flour noodles are subjected to a soaking through steam heating treatment, oil mixing, cooling and packaging to form cooked products. This kind noodles need to be subjected to secondary braising, steaming (braised noodles), frying and braising (fried noodles), boiling and mixing in boiling water (hot-dry noodles and alkaline noodles), soaking and leaching (cool braised noodles), etc.The production equipment is the most popular industrial equipment at present market,widely accepted by consumers.

Product Parameters

Model No. Production Capacity:8h Size of Factory

(Length*Width*Height)(m)Width of Roller (mm) Installed Capacity(kw) Workers(withoutpacking process) XMS-Il 350 6000 60x12x4.5 350 ~68 4 XMS-Il 450 8000 70x12x4.5 450 ~75 6 XMS-Il 550 12000 70x16x4.5 550 ~80 7 XMS-lI 650 15000 80x16x4.5 650 ~95 7 XMS-II 850 18000 80x18x5 850 ~115 8 Cooked Fresh Noodle Steaming Production Process

Automatic Raw Material Supplying-Mixing & Measurement Of Salt And Water-Double-Shaft Double-Speed Dough Making-Dough Ripening-Monolithic Rolling-Dough Sheet Ripening-Continuous Rolling-Continuous Steaming-Soaking&Softening-Loosening-Spray Oil-Secondary Noodle Steaming-Loosening-Cooling-Conveying-Fixed Length Cutting-Packaging-Warehousing

Equipment Configuration Sheet

Equipment Name

Remarks

Pictures (for reference only)

1

Salt water mixer

Barrel form: round or quadrangular octagonal.

Includes: stirrer, stirring bucket, infusion tube, infusion pump.

Material: Stirrer, stirring barrel, infusion tube, pipe fittings, valves are made of SUS304L stainless steel;

The infusion pump is made of acid-resistant plastic.

Uses and characteristics: easy to blend with water, such as adjuvants and other materials and water mixing and fusion, supply metering device, automated control, automatic water intake, automatic switching, reducing manual intervention.

2

metered supply

Installation

Material: metering tank, infusion tube and valve are made of stainless steel SUS304.

Uses and characteristics: The liquid stirred by the salt-water mixer is quantitatively supplied to the pasta pot and pasta, with precise measurement, realizing quantitative and automatic addition of water, stable and without residue, and the amount of water can be adjusted according to the different pasta products.

3

Double speed pasta machine

Includes: 1 x hopper, automatic door opening for discharging.

Material: face box, shaft, blade, lower hopper are made of SUS304. Ordinary steel or cast iron: transmission parts, seat, cylinder. Nylon: positioning sleeve

Uses and Characteristics: The made dough has good tensile strength, not easy to break, good transparency and chewy texture. This machine adopts elliptical double-axis mixing paddles, which makes the mixing more even and the effect more ideal. Adopting reducer belt transmission, which not only ensures the transmission ratio, but also improves the stability of mechanical operation. The box and mixing shaft support bearing seat are designed separately to prevent the material from being contaminated.

4

Static Cooker

Material: The noodle hopper, the plate thickness of pot body is 1.5mm, and the decoupling shaft is made of SUS304 stainless steel. The frame is made of carbon steel. Roller is made of SUS201 stainless steel. The conveyor belt is made of food grade polyester tape.

Appearance: Brushed stainless steel plate and bright rectangular tube.

Uses and Characteristics: Wake-up conveyor is used to leave the dough conveyed by the mixing machine to cook, and at the same time, it plays a role of uniform feeding for the next pressing process. (Frequency conversion speed control) Continuous uninterrupted feeding, customized spiral crushing feeding, semi-closed moisture preservation is conducive to better formation of gluten network.

5

Monolithic . Continuous calender

Including: guide hopper feeding device, automatic conveyor belt for pasta sheet, manual adjustment mechanism for pressure roller gap. The machine gang is floor type.

Material: The drop hopper, feeding toggle bar, over surface bottom plate, head guard, machine gang, frame, transmission parts are made of carbon steel. Scraper: brass material. Pressure roller: cold hard alloy ordinary casting roller. Conveyor belt: food grade polyurethane belt. Guards: Pressure roller guards are nylon.

Uses and characteristics: (Frequency conversion speed control) (photoelectric tracking) automatically calendering the summed up crumbled noodle into noodle belt, calendering the noodle belt through multiple pressure rollers to the thickness required by the process. Automatic sheet loading and tracking, PLC programmed automatic program, the whole unit is designed as a group of one, high safety protection level, stable operation.

6

pasta steamer

Package includes: insulated steam tank, mesh conveyor belt, steam injection pipe, valve, pressure gauge, temperature gauge, exhaust hood, pipe, fan, axial fan, brush net device.

Material: stainless steel: trough, nozzle, conveyor chain, mesh belt, guide rail, vapor exhaust cover, vapor exhaust pipe.

Nylon: nylon reel. Body Insulation: Aluminum Silicate Aluminum Silicate: Body Insulation.

Automatic cleaning device for mesh belt: nylon reel Water tank: stainless steel Brush: nylon.

Uses and features: independent transmission, adjust the length of the surface block without downtime water sealing, mechanical lifting and opening the door.

7

Continuous foaming machine

Including: mesh chain, water tank, rack body, water pipeline, heating system, water tank transfer mesh belt, pressure chain device, rack body, pipeline, valve, water inlet, sewage device.

Material: The contact surface of the rack with water and face belt is made of SUS304 stainless steel, and the transmission parts are made of high-quality carbon steel surface treatment.

8

Cold Noodle Conveyor

Triple reciprocating.

Including: machine body, stainless steel conveyor mesh belt, noodle loosening machine, fan, conveyor belt, fan, transmission system.

9

Secondary Steamer

Including: insulated steam tank, mesh conveyor belt, steam injection pipe, valve, pressure gauge, temperature gauge, exhaust hood, fan, brush net device.

Material: Stainless steel: trough, nozzle, conveyor chain, mesh belt, guide rail, vapor exhaust cover, vapor exhaust pipe. Ordinary steel or cast iron: transmission parts, gasket plate, foot adjustment bolts. Nylon: nylon reel; rubber: sealing strip; aluminum silicate: body insulation.

10

Cold Noodle Conveyor

Triple reciprocating.

Including: machine body, stainless steel conveyor belt, noodle loosening machine, oil drenching device, fan, conveyor belt, fan, transmission system.

11

cooling tunnel

Includes: chiller unit, frame, rail, chain, transmission components, etc.

12

Electrical control system

Consists of 4 control cabinets;

Ⅰ # Cabinet: control salt water mixing, measuring, and dough.

Ⅱ # Cabinet: control of static ripening, single slice, calendering.

Ⅲ# Cabinet: Controls steam surface, infiltration and conveyance.

Cabinet Ⅳ#: Controls steaming surface, cooling, and conveying. (excluding cables outside the cabinet)

Includes: programmable controllers, inverters, housings, contactors, meters, etc.

The whole line adopts photoelectric sensing tracking, frequency conversion speed control, PLC program processing, self-batching, water supply, metering, continuous mixing and dough, dough maturing, single piece calendering, continuous calendering, steaming, conveyor, steamer, cooling and conveying, and adding the process link programmable system control, which can realize the fine adjustment of single machine, linkage of the whole line, and synchronous lifting and lowering speed.

-

Model No. Production Capacity:8h Size of Factory

(Length*Width*Height)(m)Width of Roller (mm) Installed Capacity(kw) Workers(withoutpacking process) XMS-Il 350 6000 60x12x4.5 350 ~68 4 XMS-Il 450 8000 70x12x4.5 450 ~75 6 XMS-Il 550 12000 70x16x4.5 550 ~80 7 XMS-lI 650 15000 80x16x4.5 650 ~95 7 XMS-II 850 18000 80x18x5 850 ~115 8 -

-

Q:How long is your machine guarantee?

A: One year (Calculated from the equipment arrives the customer's side.). We always have new technology support on machine service life period. And welcome to contact us when machine have any problem.

Q: Will you send engineers to install production line in customer plant?

A: Yes, but installation will have extra cost payable by the customer, Or you can get local contractors to do the commissioning and we send one supervising engineer.

Q: Do you supply packing machine?

A: We have long-term cooperation packing machine supplier, we will help tocontact them; Or we share supplier contact information, then customer directly contact supplier.

Q: Will you support each food formula?

A: Yes, we support each product production technology and recipe to customer.

Key words:

Noodle Production Line

Online Messages

Related products

Related news

Low-temperature environment of the pasta machine should be operated in this way to run work

Dec 21,2023

After stopping the machine should be timely removal of production waste, to ensure that all parts of the pasta machine clean!

Hanging noodle equipment production of common faults and processing methods

Dec 14,2023

Most of the daily use of hanging noodle equipment often appear some unavoidable small problems, analyze the common faults of hanging noodle equipment and treatment methods to ensure the output of the production line noodles and noodle quality.

Hanging noodle machine manufacturers production equipment use precautions

Oct 11,2023

During the production process of Hanging Noodle Machine Manufacturer, place the noodle machine on a dry and ventilated horizontal floor to ensure that the machine works smoothly and reliably. Carefully check whether there are iron shavings in the feed opening of the machine, clean it up in time, and pull out the connecting plate before use. Check whether the power supply voltage matches the power supply used by the machine.

Aug 16,2023

The working principle of the automatic noodle machine is very simple, which is to drive the gears of each part of the noodle machine to rotate through the action of the motor and the speed reducer, and pour the blended flour into the plastic. Barrel. The pasta sheet is pressed into a certain thickness, so that we can gently adjust the handwheels at both ends of the pasta thickness roller to the expected scale, but the guys should pay attention to it, pay attention to the gap between the two sides of the pressure roller, they are each other, so they must be the same, otherwise the dough will go out of the way. The head of the machine is equipped with a noodle cutter, where the pressed noodles are cut into dry noodles by the cutter, which can be configured to cut different noodles, such as round noodles, wide noodles, etc. . You can also set the length of automatic cutting according to your own idea.