Fresh Noodle Production Line

Category:

E-mail :

- Product Description

- Product Parameters

- Related Videos

- FAQ

-

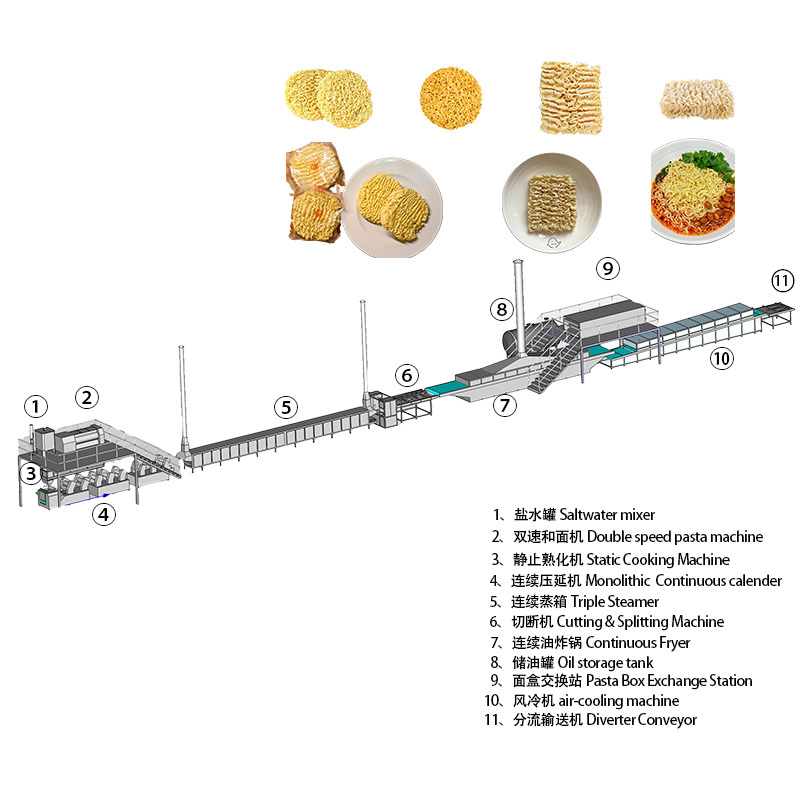

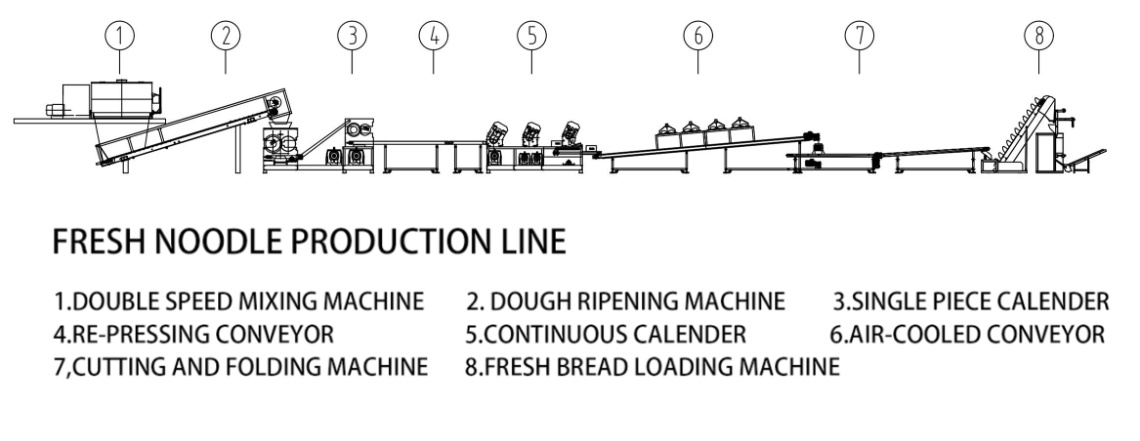

The fresh noodle and semi-dry noodle mechanical and electrical integrated equipment developed by the company and universities, mixing wheat flour and special auxiliary materials produce into noodles,dehydration of small amount of water and packing, then the packaged product can be directly sold in the market. The equipment has the advantages of simple process, low cost, high quality and good taste. Its disadvantages : the process link requirement is strict, and the quality guarantee period of the product is short, generally3-90days. The equipment is optimal industrialization equipment for staple food engineering, hotel and catering chain-like noodle restaurants at present.

Product Parameters

Model No. Production Capacity:8h Size of Factory

(Length*Width*Height)(m)

Width of Roller(mm) Installed Capacity(kw) Workers(without

packing process)

fresh noodles semolina pasta XMS-Il 220 3000 2000 40x8x4.5 220 ~60 3 XMS-ll 350 4500 3000 40x8x4.5 350 ~68 4 XMS-II 450 6000 4000 50x10x4.5 450 ~75 6 XMS-II 550 7500 5000 50x12x4.5 550 ~80 7 XMS-ll 650 9000 6000 60x12x4.5 650 ~95 7 Fresh Noodle Production Process

Automatic Raw Material Supply - Mixing & Measurement Of Salt And Water-Vaccum Dough Making-Dough Ripening-First Time Rolling-Noodle Strip Aging-Continuous Rolling-Spraying Powder-Fixed Length Cutting-Dehydration Sterilization-Packaging

Equipment Configuration Sheet

device name

remarks

Picture (for reference only)

1

Saline mixer

Barrel form: round or four corners.

Including: mixer, mixing bucket, infusion tube, infusion pump.

Materials: agitator, mixing drum, infusion tube, pipe fittings, valve is made of SUS304L stainless steel;

The infusion pump is made of acid-resistant plastic material.

Use and characteristics: fuse the materials such as easy to fuse with water and water mixing, supply the metering device, to realize automatic control, automatic water intake, automatic switching, and reduce manual intervention.

2

Measurement of supply installation

Material: the metering tank, infusion tube and valve are made of stainless steel SUS304.

Use and characteristics: the brine mixer stirred liquid, quantitative supply and surface pot and surface, accurate measurement, achieve quantitative automatic water, stable no residue, can be adjusted according to different surface water.

3

Double speed and noodle machine

Including: 1 hopper, automatically open the door for feeding.

Material: face box, shaft, blade and lower hopper are SUS304 material. Ordinary steel or cast iron: transmission parts, chassis, cylinder. Nylon: Locate the set Use and characteristics: made of the skin of good tensile resistance, not easy to break, good transparency, chewy texture. This machine uses the elliptical biaxial mixing blade, and the surface is more uniform, the effect is more ideal. The reducer belt drive not only ensures the transmission ratio, but also improves the stability of mechanical operation. The box body is separated from the supporting bearing seat of the mixing shaft to prevent material contamination.

4

Static ripening machine

Material: the surface bucket, pot plate is 1.5mm thick, and the crushing shaft is made of SUS304 stainless steel. The frame body is carbon steel. The roller is made of SUS201 stainless steel. The delivery surface belt is a food-grade polyester tape.

Appearance: frosted stainless steel plate and bright light rectangular pipe.

Use and characteristics: the surface conveyor is used to keep the dough transported by the dough machine static and cooked, and to evenly feed the next sheet pressing process.(Frequency conversion and speed regulation) continuous uninterrupted feeding, customized spiral broken feeding surface, semi-closed moisture protection is conducive to the better formation of gluten network.

5

monolithic. Continuous rolling machine

Including: guide per feeding device, surface automatic conveyor belt, roller clearance manual adjustment mechanism. The machine help is for the landing type.

Materials: hopper, feeding rod, bottom plate, head guard plate, machine, frame and transmission parts are made of carbon steel. Scraper: brass material. Press roller: cold hard alloy ordinary casting roll. Delivery strip: a food-grade polyurethane strip. Guard plate: the pressing roller guard plate is nylon.

Application and features: (frequency conversion speed regulation) (photoelectric tracking) automatically calder the good broken surface into a surface belt, extending the surface belt through multiple pressure rollers to the thickness required by the process. Automatic chip, tracking, PLC programming automatic program, the overall design of the unit for a group of integrated, high safety protection level, stable operation.

6

Secondary plane with ripening machine

Material: frame and roller are of SUS304 stainless steel. The delivery surface belt is food grade polyester tape or stainless steel rod delivery chain.

Appearance: frosted stainless steel plate and bright light rectangular pipe.

Windows: glass sliding door

Use and characteristics: (frequency conversion and speed regulation) push the pressed belt into the ripening box, so that the belt can form a better gluten network and increase the taste. Semi-closed moisture protection is conducive to the better formation of gluten network.

7

Air-cooled conveyor

Including: stainless steel transmission network chain + fan.

Material: rack, side plate, floor, conveyor chain, rail etc. are SUS304 stainless steel; fan is carbon steel.

Use and features: (variable frequency speed regulation) dehydrated the surface of sliced noodles to prevent noodles adhesion.

8

Finished conveyor

Fixed length cut-off, frequency conversion and speed regulation.

Material: frame body, side plate and drum are SUS304 stainless steel materials; transmission parts and drive mechanism are high quality carbon steel surface treatment. The conveyor belt is a food-grade polyester belt.

9

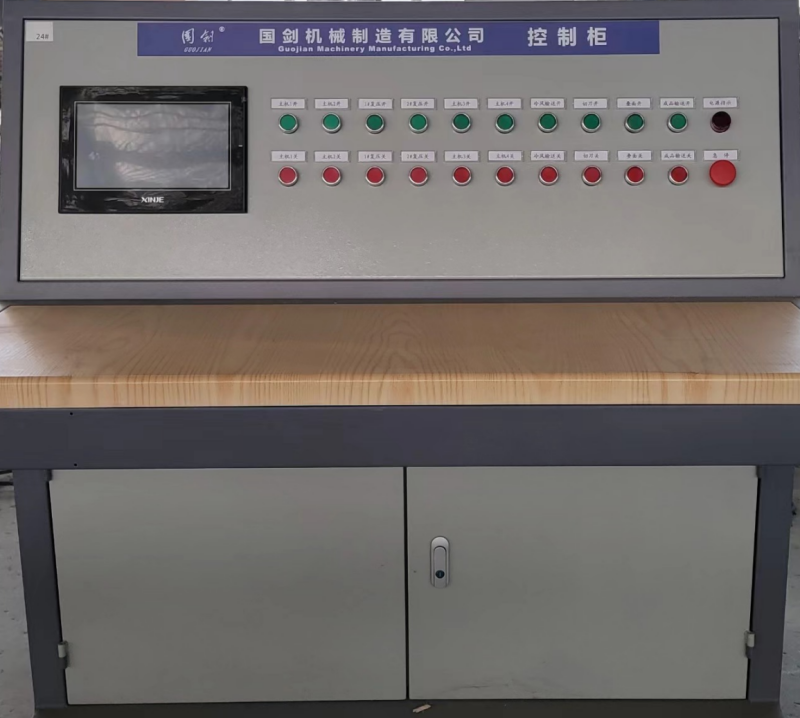

Electrical control system

There are 2 electric cabinets: no. 1 control and surface machine.

No.2 control curing machine, calender, secondary curing, double-sided powder, air cooling, length cut off, finished product transportation. The whole line adopts frequency conversion speed control, PLC control.

-

Model No. Production Capacity:8h Size of Factory

(Length*Width*Height)(m)Width of Roller(mm) Installed Capacity(kw) Workers(without

packing process)fresh noodles semolina pasta XMS-Il 220 3000 2000 40x8x4.5 220 ~60 3 XMS-ll 350 4500 3000 40x8x4.5 350 ~68 4 XMS-II 450 6000 4000 50x10x4.5 450 ~75 6 XMS-II 550 7500 5000 50x12x4.5 550 ~80 7 XMS-ll 650 9000 6000 60x12x4.5 650 ~95 7 -

-

Q:How long is your machine guarantee?

A: One year (Calculated from the equipment arrives the customer's side.). We always have new technology support on machine service life period. And welcome to contact us when machine have any problem.

Q: Will you send engineers to install production line in customer plant?

A: Yes, but installation will have extra cost payable by the customer, Or you can get local contractors to do the commissioning and we send one supervising engineer.

Q: Do you supply packing machine?

A: We have long-term cooperation packing machine supplier, we will help tocontact them; Or we share supplier contact information, then customer directly contact supplier.

Q: Will you support each food formula?

A: Yes, we support each product production technology and recipe to customer.

Key words:

Noodle Production Line

Online Messages

Related products

Related news

African mission Come To Our Factory

Mar 12,2024

Wuzhi county business bureau, from Africa project delegation will arrive at our factory at ten o 'clock at noon. First, we will show the finished product to the customer. Secondly, we will play through video to let customers know about all our products, our company is a professional company of noodle machine, and our main products are fried instant noodles production line, non-fried instant noodles production line, frozen fresh noodles production line, stick noodles production line, baby noodles production line and soon. Thirdly, it will give a brief introduction about the production line of fried instant noodles exported to Nigeria. The production line of our company's fried instant noodles is warmly welcomed in central Asia, with high degree of automation and advanced production technology. The instant noodles produced are tasty and crispy.

The New Research And Development Of Noodles Line

Mar 05,2024

According to legend, Quanzhou noodle line has a history of more than 800 years. The authentic noodle line is made by hand. The noodle body is as thin as hair. When cooked, it becomes transparent. Noodles line contains rich and auspicious, long life of a hundred years of good wishes. It is a must to welcome guests and guests, bless congratulations, celebrate holidays and present relatives and friends. In the southern Fujian region, people usually bring thread and egg to celebrate their birthday or other happy events to express their wishes.

Pasta Leaf Production Line: Benefits of Pasta Fermentation

Feb 14,2024

Yeast not only changes the structure of the dough, but also makes them fluffier and tastier, which also greatly increases the nutritional value of buns and bread. Fermented buns and breads are then more nutritious than unfermented foods such as cakes and noodles, because of the yeast used. Eating fermented foods regularly has the following benefits:

Asean food machinery exhibition in Bangkok

Feb 07,2024

The company organized to participate in the Asean Bangkok exhibition this year, the sales manager of our company Mr. Pang leads the team, during the fair, we and the industry technical communication, to understand the different parts of the people's demand for pasta, at the same time, through the exhibition this good platform, here we have seen some cutting-edge products, we also expand the brand influence, reputation, the company's products and services to the nation, to the southeast Asia. At the exhibition, many customers expressed interest in our machinery, sat down to communicate with us, we also exchanged business CARDS, looking forward to future cooperation.